sunflower seed grain silo

A sunflower seed grain silo is a facility specifically designed for storing sunflower seeds. Sunflower seeds are the seeds of the sunflower plant, commonly used

sunflower seed grain silo Introduction

A sunflower seed grain silo is a facility specifically designed for storing sunflower seeds. Sunflower seeds are the seeds of the sunflower plant, commonly used for extracting edible oil or as food ingredients. The design and functionality of a sunflower seed grain silo aim to provide an appropriate storage environment, protecting the sunflower seeds from moisture, mold, and pest infestation, ensuring their quality and safety. These silos may be equipped with ventilation systems, moisture control, and pest prevention devices, as well as safety features, to meet the storage needs of sunflower seeds and ensure they remain in good condition during storage.

Functions of sunflower seed grain silo

Storage

The fundamental function of a silo is to provide a safe and dry storage environment for harvested sunflower seeds, protecting them from adverse conditions such as moisture, high temperatures, and other detrimental factors.

Quality Preservation

By controlling temperature and humidity, silos help maintain the quality of sunflower seeds, preventing mold and spoilage, ensuring their nutritional value and safety for consumption.

Supply and Demand Regulation

Silos can balance market supply and demand by storing excess supply and releasing inventory during periods of high demand, stabilizing market prices.

Processing Preparation

Serving as a raw material base for processing enterprises, silos facilitate the further processing of sunflower seeds, such as for oil extraction or direct consumption.

Pest and Rodent Protection

Silos are equipped with corresponding protective measures to prevent damage from pests and rodents to the sunflower seeds.

Fire Safety

Silo designs incorporate fire prevention facilities to prevent the occurrence of fire accidents.

Loading and Unloading Operations

Silos are equipped with mechanized loading and unloading systems to improve operational efficiency and reduce labor costs.

Information Management

Modern silos typically have an information management system to monitor inventory levels, silo environments, and the movement of goods in real-time.

Trade Facilitation

As logistics nodes, silos aid in the aggregation and trade circulation of sunflower seeds.

Environmental Protection

The design and operation of silos take into account environmental protection to minimize their impact on the surrounding environment.

Emergency Provision

In the event of natural disasters or other emergencies, silos can serve as points for emergency material reserves.

Economic Benefits

Through centralized storage and scaled operations, silos help reduce logistics costs and improve economic efficiency.

These functions illustrate the multifaceted role of sunflower seed silo in agricultural production, processing, trade, and market regulation.

Features of sunflower seed grain silo

Large Capacity Storage

Purpose-built with substantial storage volume, sunflower seed silos accommodate substantial quantities of the crop in a centralized manner, catering to the demands of large-scale agricultural operations and enhancing warehouse efficiency and spatial utilization.

Superior Sealability

The silo structure is meticulously crafted to ensure an exceptional level of airtightness, preventing external moisture, pests, and contaminants from infiltrating and safeguarding the sunflower seeds against moisture damage, mold growth, and infestations.

Advanced Ventilation System

Incorporating state-of-the-art ventilation technology, the silo facilitates the regulation of internal temperature and humidity, mitigating the risk of overheating and spoilage while fostering an optimal storage atmosphere for the preservation of sunflower seed quality.

Integrated Pest Management

Equipped with integrated pest management strategies, such as the installation of insect-proof screens, fumigation facilities, and regular inspections, the silo effectively combats potential pest infestations, protecting the sunflower seeds from damage and maintaining their integrity.

Smart Monitoring

Modern sunflower seed silo often feature intelligent monitoring systems comprising temperature and humidity sensors, carbon dioxide detectors, and grain moisture meters, which continually monitor and record environmental parameters within the silo, providing real-time data for informed decision-making in grain storage management.

Efficient Material Handling Equipment

To streamline the loading and unloading processes, sunflower seed silos are fitted with efficient material handling equipment, including conveyors, elevators, and cleaning sieves, which ensure rapid, damage-free transfer of sunflower seeds while minimizing manual labor requirements and enhancing overall operational efficiency.

Fire Safety Measures

Comprehensive fire safety provisions, such as fire extinguishers, fire hydrants, and automatic fire suppression systems, are incorporated into the design of sunflower seed silos to ensure compliance with stringent fire safety regulations and provide peace of mind against potential fire hazards.

Structural Robustness

With a robust and durable structural design, sunflower seed grain silo are built to withstand the considerable weight of stored sunflower seeds, as well as the rigors of diverse weather conditions, including wind, snow, and earthquakes, ensuring long-lasting, secure storage.

In summary, sunflower seed grain silo excel in offering large-capacity storage, superior sealability, advanced ventilation, integrated pest management, smart monitoring, efficient material handling, fire safety measures, and structural robustness, making them the ideal storage solution within the sunflower seed supply chain.

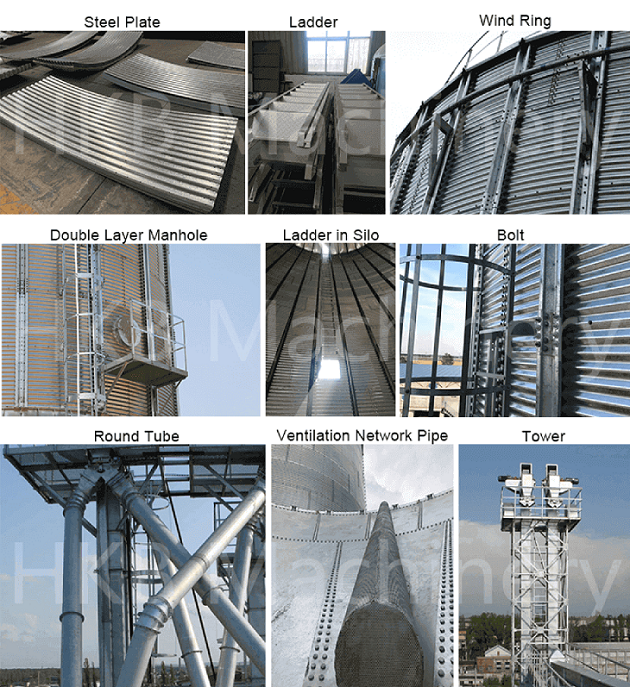

Structure of sunflower seed grain silo

Wall

Forms the main enclosing structure of the silo, typically constructed using materials such as reinforced concrete, prestressed concrete, or steel, providing sufficient strength and rigidity to withstand the weight of sunflower seeds and external loads. The inner wall may undergo moisture-proof and anti-mold treatments, such as coating with moisture-resistant paint or laying moisture-proof layers.

Roof

Covers the top of the silo, serving to protect against rain, sun exposure, and insulation. Made of the same material as the wall, the design considers drainage, ventilation, and lighting needs, possibly incorporating features such as skylights and vents.

Base

Designed to prevent moisture, pests, and facilitate easy removal of grain. It may use moisture-resistant materials or incorporate moisture-resistant layers. For large silos, the base may be designed as a tapered cone for self-flow of sunflower seeds.

Inlet

Located on the roof or sidewall, equipped with grain-blocking plates, dust covers, etc., to ensure sunflower seeds are not spilled or contaminated during loading.

Outlet

Located at the bottom or sidewall, equipped with gates, chutes, conveyors, etc., for the rapid and orderly discharge of sunflower seeds from the silo.

Cleaning Equipment

Includes vibrating screens, magnetic separators, air classifiers, etc., used for preliminary cleaning of incoming sunflower seeds, removing impurities and foreign objects, ensuring seed quality.

Ventilation System

Installed with equipment such as axial flow fans, centrifugal fans, etc., for forced air exchange through ventilation ducts, accurately controlling internal temperature and humidity, preventing sunflower seeds from heating and molding.

Management System

Some modern sunflower seed grain silo may be equipped with intelligent management systems, used to monitor the environmental conditions inside the silo and the status of the grain silo, improving management efficiency and accuracy.

Safety Facilities

Safety facilities such as fire prevention systems, surveillance cameras, etc., are installed to ensure the safe storage of sunflower seeds and the safe operation of the grain silo.

Auxiliary Facilities

The silo is equipped with ladders, platforms, lighting, and electrical equipment, facilitating inspection and maintenance of the roof, walls, etc., by personnel.

In summary, the structure of a sunflower seed grain silo consists of multiple parts including the silo body, inlet and outlet system, ventilation system, management system, fumigation system, fire safety facilities, and auxiliary facilities. These parts work together to achieve safe, efficient, and economical storage of sunflower seeds.

Application scope of sunflower seed grain silo

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Sunflower seed grain silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.