barley grain silo

A barley grain silo is a facility specifically designed for storing barley. Barley is an important cereal crop with various uses, including food processing

barley grain silo Introduction

A barley grain silo is a facility specifically designed for storing barley. Barley is an important cereal crop with various uses, including food processing and feed production. Barley grain silos typically have specific designs and structures to ensure the quality and safety of the stored barley during storage. They are usually equipped with functions such as ventilation, moisture control, and moisture resistance, utilizing modern technology and management systems to maintain the barley in good condition during storage. Barley grain silos are important for ensuring food security and agricultural product storage.

Characteristics of barley grain silo

Designed specifically for barley

The barley grain silo is a facility specifically designed for storing barley, with its structure and functionality optimized for the characteristics and storage requirements of barley.

Ensuring grain quality and safety

Through functions such as ventilation, moisture control, and moisture resistance, the barley grain silo can maintain stored barley in good condition, preventing issues such as mold and fermentation, and ensuring grain quality and safety.

Efficient storage structure

The barley grain silos typically has a rational storage structure to maximize storage space utilization while ensuring that stored barley is easy to manage and access.

Modern management systems

Equipped with advanced automation equipment and intelligent management systems, the barley grain silo can enhance operational efficiency, reduce labor costs, and improve the accuracy and efficiency of storage and management.

Environmentally friendly

The barley grain silos typically considers environmental protection factors in its design and operation, employing energy-saving and emission-reducing technologies and measures to minimize its environmental impact.

Moisture and pest prevention

The silo adopts a sealed design to effectively prevent the effects of humid weather on the grain and prevent pests from entering, thereby protecting grain quality.

Insulation

The silo’s interior is equipped with insulation materials to effectively block external temperature changes, providing excellent insulation and thermal insulation to protect grain quality.

Easy to assemble and disassemble

The modular design makes the assembly and disassembly of the silo very convenient, allowing for quick adjustments and relocations as needed.

Safe and reliable

Barley grain silos are typically equipped with safety features such as fire and explosion prevention measures to ensure the safe operation of the silo.

Barley grain silo structure

Roof

The roof is designed to withstand extreme snow disasters, with a sturdy structure and interconnecting radial ribs at the top and bottom that mutually reinforce each other. These ribs themselves are interconnected in a Z-shaped manner. The roof panels are combined with the ribs, featuring overlapping profiles top and bottom to ensure precise coordination.

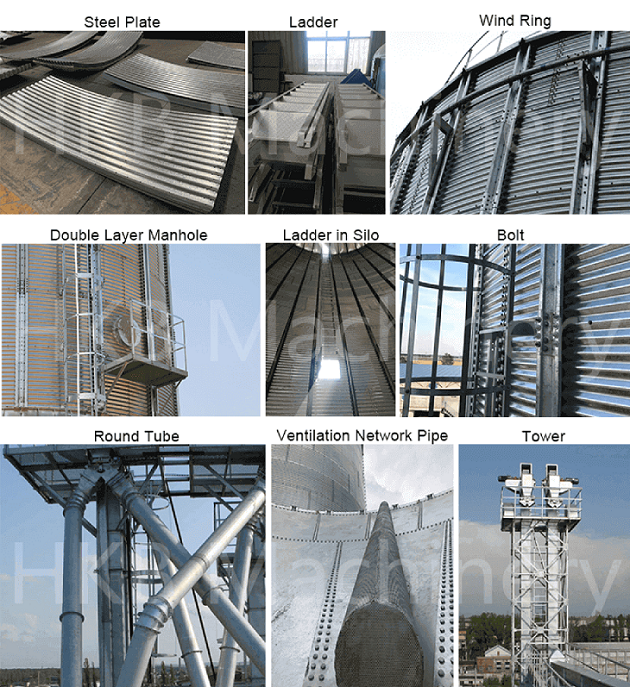

Body Steel Plate

Commercial 275g/m2 double galvanized steel coating enhances longevity and durability. Coatings of 450g/m2 and 600g/m2 are available for customized orders. Each sidewall panel is made of high-strength steel, capable of withstanding extreme power and pressure.

Stiffeners

HKB’s high-tension stiffeners (can be located inside or outside the silo) make the grain silo more robust, even maintaining a good state under extreme hurricanes. The base stiffener boots are coated to prevent rust over time.

Wind Ring

Suitable for tall silos or those requiring resistance to strong winds. The wind ring and brackets reduce bolt holes in the stiffeners; molding technology ensures the silo’s power load capacity.

High-strength bolts and screws

HKB’s high-strength bolts paired with sealing washers, coated hardware provide additional rust protection, ensuring your grain silo withstands the test of time.

Manhole

Double-layered secure locking manhole system.

Wide Flange H Beam Support Structure

The wide flange H-beam support structure has strength and durability, capable of supporting heavy loads at the bottom of the hopper bin for extended periods, considering wind and seismic requirements.

Advantages of barley grain silo

Grain Security

The barley grain silo effectively ensures the storage safety of barley and other grains, preventing them from getting damp, molding, or being invaded by pests, thus ensuring their quality and safety.

Storage Efficiency

Typically, the barley grain silo is designed with a rational layout and equipped with advanced management systems, maximizing the utilization of storage space and enhancing storage efficiency.

Environmental Protection

Environmental factors are considered in both the design and operation of the barley grain silo. It adopts energy-saving and emission-reducing technologies and measures to minimize its environmental impact.

Strong Durability

Constructed with high-quality galvanized steel sheets, the barley grain silo exhibits excellent corrosion resistance and ability to withstand harsh weather conditions, maintaining stability under various climates.

Excellent Sealing

The silo is equipped with a sophisticated sealing device, effectively isolating external moisture and pests, thus ensuring the quality and safety of stored grains.

Flexibility and Adjustability

Based on customer needs, the barley grain silo can be customized in different specifications and capacities to flexibly meet various usage requirements in different scenarios.

Safety and Reliability

With reliable structural design and reasonable support systems, the barley grain silo ensures stability and reliability during use, minimizing the risk of tilting or damage.

Modern Management

Equipped with intelligent management systems, the silo enables real-time monitoring and management of grain storage conditions, improving management efficiency and accuracy.

Application scope of barley grain silo

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Barley grain silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.