Rice silo

Rice silo are specialized storage facilities designed for the preservation of rice grains. Typically constructed in cylindrical or rectangular shapes, these silos are built with galvanized sheet materials internally, offering excellent sealing and corrosion resistance.

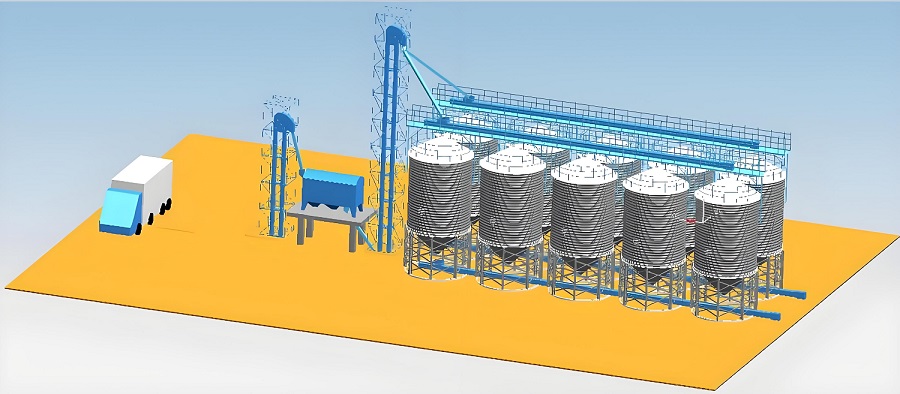

Rice silo Introduction

Rice silo are specialized storage facilities designed for the preservation of rice grains. Typically constructed in cylindrical or rectangular shapes, these silos are built with galvanized sheet materials internally, offering excellent sealing and corrosion resistance. This ensures that the rice stored within can be maintained in optimal conditions for long-term preservation, thereby keeping its quality stable over time.

Rice silo features

Capacity

Rice silos are typically designed with large storage capacities, able to accommodate thousands of tons or more of rice, meeting the needs for mass storage.

Moisture Resistance

Given that rice is susceptible to moisture, the design of silos places a significant emphasis on moisture prevention, often utilizing materials with good sealing properties and including dehumidification system.

Ventilation

Good ventilation is crucial for maintaining the freshness of rice. Silos are equipped with ventilation systems to ensure free air circulation through the rice heaps, reducing uneven distribution of temperature and humidity.

Pest and Rodent Control

To prevent damage from pests and rodents, silos implement a series of protective measures, such as using insect-proof materials and setting up rodent-proof facilities.

Temperature Control

Rice silos may be fitted with temperature control systems to maintain suitable temperatures, preventing the rice from overheating or cooling excessively.

Loading and Unloading System

For the convenience of rice ingress and egress, silos are designed with efficient loading and unloading systems, including conveyor belts, elevators, and other equipment.

Rice silo structure

Upper Structures

These refer to the architectural structures located at the top of the silo, including the top platform and any associated facilities such as rooms or platforms for operation and maintenance. They serve to protect the stored rice from external environmental factors like rain and dust.

Silo Cover

The silo cover is the sealing structure at the top of the silo, which can be fixed or removable, ensuring that the stored rice is protected from external elements.

Silo Walls

The silo walls are the main structural component of the silo, usually made of strong and durable materials to withstand the weight of the rice and external environmental impacts. The design of the silo walls takes into account moisture resistance, pest prevention, and ventilation.

Cylinder Walls

For certain specific silo designs, such as cylindrical silos, the cylinder walls are part of the silo walls, referring to the vertical walls surrounding the central axis of the silo.

Hopper

Located at the bottom of the silo, the hopper is a structure designed to guide the rice out of the silo. The design of the hopper helps to ensure smooth discharge of rice and prevent blockages.

Lower Structures

These include the architectural structures at the base of the silo, such as foundations, supports, and other structural elements that provide stable support for the entire silo structure.

Foundation

he foundation is the bottom part of the silo structure, in direct contact with the ground, providing a solid base for the entire silo structure. The design of the foundation takes into account ground-bearing capacity and potential settlement issues.

Loading and Unloading System

To facilitate the entry and exit of rice, silos are usually equipped with an efficient loading and unloading system, which may include conveyor belts, elevators, and other equipment.

Rice Silo Function

Ensuring food security

Rice silos play a crucial role in safeguarding the supply of rice and stabilizing market prices by enabling the mass storage of rice grains.

Enhancing storage efficiency

The centralized storage and scientific management practices in rice silos significantly improve the efficiency of rice storage and reduce losses.

Facilitating management

Rice silos are typically equipped with modern management systems that allow for real-time monitoring of the storage conditions of rice, making management and dispatching more convenient.

Responding to emergencies

In the event of natural disasters or other emergencies, rice silos serve as strategic reserves that can quickly allocate rice to meet the demand.

Application scope of Rice Silo

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Rice Silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.