flour grain silo

A flour grain silo is a facility specifically designed for storing flour or flour-related products. The design and structure of such silos typically consider

flour grain silo Introduction

A flour grain silo is a facility specifically designed for storing flour or flour-related products. The design and structure of such silos typically consider the characteristics and storage requirements of flour to ensure that it maintains good quality and safety during storage. Flour grain silos generally have a well-sealed structure to effectively prevent the intrusion of moisture, pests, and other contaminants. Additionally, they may be equipped with ventilation systems to ensure air circulation inside the silo, helping to maintain the freshness and quality of the flour. Some modern flour grain silos may also feature smart management systems that can monitor parameters such as temperature and humidity in the storage environment, and adjust them in real time to ensure optimal storage conditions.

Characteristics of Flour grain silo

Sealed Structure

Flour grain silo are typically designed with a sealed structure to prevent moisture, pests, and contaminants from entering, ensuring the quality and safety of the stored flour.

Ventilation System

Many flour grain silos are equipped with ventilation systems to facilitate air circulation inside the silo, preventing heat buildup and maintaining the freshness of the flour.

Temperature and Humidity Control

Advanced flour grain silo may have systems for monitoring and controlling temperature and humidity levels to create optimal storage conditions for flour.

Hygiene and Cleanliness

Flour grain silo prioritize hygiene and cleanliness to prevent contamination and maintain the quality of the flour.

Capacity and Storage Efficiency

These silos are designed to efficiently store large quantities of flour while optimizing storage space.

Safety Features

Flour grain silo may incorporate safety features such as fire suppression systems, emergency exits, and alarms to ensure safe storage operations.

Durability and Structural Integrity

They are built to withstand the weight of stored flour and external environmental factors like wind and seismic activity, ensuring long-term reliability and stability.

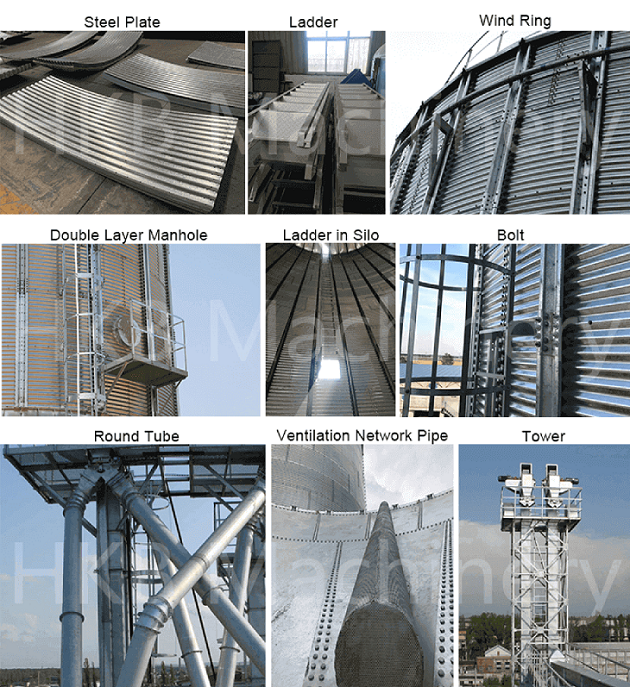

Structure of flour grain silo

Silo Body

The main cylindrical or tower-like structure that houses the stored flour. It is typically made of materials like reinforced concrete, steel, or sometimes even fiberglass, providing strength and durability.

Roof

The top cover of the silo, which protects the stored flour from environmental elements such as rain, snow, and sunlight. It may be sloped to facilitate water drainage and prevent moisture buildup.

Floor

The bottom part of the silo where the flour is stored. It should be flat and level to ensure even distribution of the flour and may include features like aeration systems or moisture barriers to maintain flour quality.

Access Points

These include entrances, hatches, or doors for loading and unloading flour into and out of the silo. They are strategically placed for easy access and efficient operation.

Ventilation System

Designed to provide airflow inside the silo to regulate temperature and humidity, preventing the flour from spoiling or developing mold. It may consist of vents, fans, or ducts for air circulation.

Temperature and Moisture Monitoring Systems

These systems are installed to continuously monitor the internal conditions of the silo, ensuring that the flour is stored within optimal temperature and humidity ranges to preserve its quality.

Safety Features

Such as ladders, platforms, handrails, and safety cages to facilitate safe access for maintenance and inspection purposes. Additionally, fire suppression systems and emergency exits may be incorporated to enhance safety measures.

Insulation and Sealing

Some silos are insulated to regulate temperature fluctuations, while others are sealed to prevent moisture ingress and pest infestation, thereby maintaining flour quality and safety.

Support Structure

Provides structural stability to the silo, consisting of beams, columns, and braces that distribute the weight of the stored flour and withstand external forces like wind and seismic activity.

Advantages of Flour Grain silo

Quality Assurance

The silo’s sealing performance and ventilation system effectively prevent moisture, mold, and pests from entering, ensuring the freshness and quality of the flour.

Improved Storage Efficiency

The rational design of the silo structure maximizes storage space utilization, making flour storage more compact and efficient.

Environmental Control

Equipped with an intelligent temperature and humidity monitoring and regulation system, it can monitor the environmental conditions inside the silo in real time and automatically adjust to create the optimal storage environment.

Safety and Reliability

The silo adopts a sturdy and durable structural design and safety facilities such as fire prevention systems and emergency exits to ensure safe operation.

Flexibility

Customizable in different specifications and capacities to meet various scales and demands of flour storage needs.

Cost Savings

By optimizing storage structures and implementing automated management systems, operational costs can be reduced while improving management efficiency and accuracy.

Environmental Friendliness

It adopts energy-saving and emission-reducing technologies and measures to minimize its impact on the environment, meeting the requirements of sustainable development.

Application scope of Flour grain silo

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Flour grain silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.