corn storage silo

A corn storage silo is a facility specifically designed for storing corn. These silos are typically designed with airtight and moisture-resistant structures, aiming to ensure that stored corn remains dry, fresh, and safe for extended periods.

corn storage silo Introduction

A corn storage silo is a facility specifically designed for storing corn. These silos are typically designed with airtight and moisture-resistant structures, aiming to ensure that stored corn remains dry, fresh, and safe for extended periods. They often come equipped with ventilation systems, intelligent monitoring systems, and pest control devices to maintain stable storage conditions and the quality of the corn. The design and structure of corn storage silos take into account the characteristics and storage requirements of corn, aiming to minimize grain loss and maximize storage efficiency.

Characteristics of corn storage silo

High Sealing Performance

Corn storage silo typically feature a well-sealed structure, effectively preventing the intrusion of moisture, pests, and other contaminants to ensure the stored corn maintains good quality.

Ventilation System

Some storage silos are equipped with ventilation systems to ensure air circulation inside the silo, helping to reduce the temperature and humidity of the stored corn, thereby minimizing the risk of mold and spoilage.

Smart Monitoring System

Modern corn storage silo may be equipped with smart monitoring systems to monitor the temperature, humidity, and other parameters of the storage environment, promptly detecting and addressing potential issues.

Durability

The structure of storage silos typically employs weather-resistant and corrosion-resistant materials, capable of withstanding long-term use and harsh environmental conditions.

Storage Capacity

Storage silos are designed with various capacities to meet the needs of different-scale farms or commercial purposes, providing flexible storage options.

Safety

Storage silos may be equipped with safety facilities such as fire prevention systems and surveillance cameras to ensure safety and reliability during the storage process.

Environmental Friendliness

Some modern corn storage silo adopt energy-saving and environmentally friendly designs and technologies, reducing their impact on the environment and meeting the requirements of sustainable development.

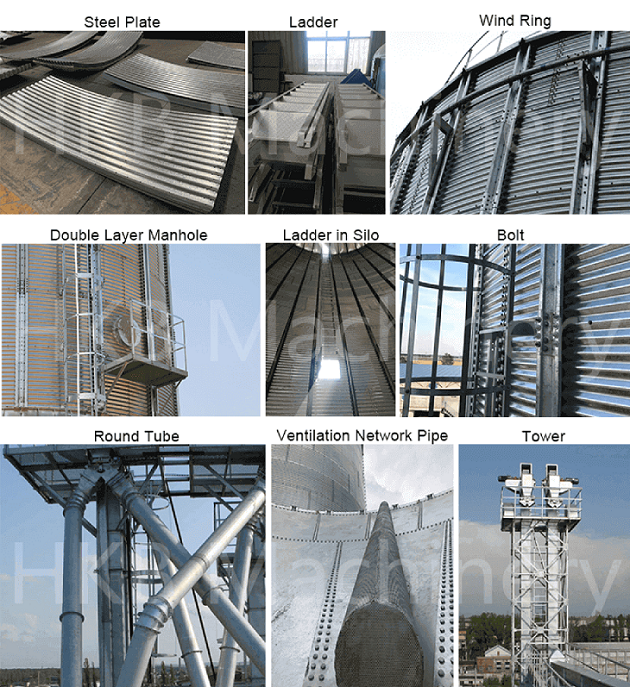

The structure of corn storage silo

Cylindrical Body

This is the main storage compartment where the corn is stored. It is typically cylindrical in shape and made of durable materials such as steel or concrete.

Roof

The roof covers the top of the silo, protecting the stored corn from environmental elements such as rain, snow, and sunlight. It may be made of steel, concrete, or other weather-resistant materials.

Access Door

This is an opening in the silo’s sidewall or roof that allows for loading and unloading of corn into and out of the silo. It is equipped with mechanisms for sealing to prevent moisture and pests from entering.

Ventilation System

The silo may have ventilation openings or systems to allow for airflow within the storage compartment. Proper ventilation helps regulate temperature and humidity levels, reducing the risk of mold and spoilage.

Foundation

The foundation provides stability and support for the entire structure. It is typically made of reinforced concrete and designed to withstand the weight of the stored corn and environmental loads.

Ladder and Platform

These are used for accessing the top of the silo for inspection, maintenance, and repair purposes. They may be integrated into the silo’s structure or attached externally.

Temperature and Moisture Monitoring Systems

Some silos are equipped with sensors and monitoring systems to track temperature and moisture levels inside the storage compartment. This allows for early detection of any issues that may affect the quality of the stored corn.

Safety Features

Safety features such as handrails, safety cages, and fall protection systems may be installed to ensure the safety of personnel working on or around the silo.

Ancillary Equipment

Depending on the specific requirements, additional equipment such as conveyors, grain handling systems, and grain dryers may be installed to facilitate loading, unloading, and processing of the corn.

Advantages of corn storage silo

Increased Storage Capacity

Corn storage silos offer a larger storage capacity compared to traditional storage methods like bins or bags. This allows for bulk storage of corn, accommodating larger quantities efficiently.

Preservation of Grain Quality

Silos provide an environment that helps preserve the quality of stored corn by protecting it from moisture, pests, and other environmental factors. Proper ventilation and sealing mechanisms contribute to maintaining grain quality over extended periods.

Space Efficiency

Silos are vertically designed structures, allowing for efficient use of space. They can be erected in compact areas, maximizing storage capacity while minimizing the footprint on the ground.

Flexibility

Corn storage silos offer flexibility in terms of design, size, and configuration. They can be customized to meet specific storage requirements, including variations in capacity, access points, and ventilation options.

Reduced Labor Requirements

Once corn is stored in a silo, it requires minimal handling compared to alternative storage methods. This reduces the labor required for loading, unloading, and monitoring the stored grain.

Longevity and Durability

Silos are constructed using durable materials such as steel or reinforced concrete, ensuring longevity and resistance to weathering. Properly maintained silos can last for many years, providing reliable storage for corn harvests.

Improved Grain Management

Silos equipped with monitoring systems allow for better grain management by providing real-time data on temperature, moisture levels, and other relevant parameters. This enables timely interventions to maintain grain quality and prevent spoilage.

Cost Efficiency

While initial investment costs may be higher compared to traditional storage methods, the long-term cost efficiency of silos becomes apparent through reduced grain losses, lower labor requirements, and improved operational efficiency.

Application scope of corn storage silo

Coban Small Storage Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds,Coffee Beans, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Corn storage silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |