soybean storage silo

A soybean storage silo is a facility specifically designed for storing soybeans or soybean products. It is typically constructed of metal or concrete and features sealing and insulation properties.

soybean storage silo Introduction

A soybean storage silo is a facility specifically designed for storing soybeans or soybean products. It is typically constructed of metal or concrete and features sealing and insulation properties. This type of storage silo protects soybeans from moisture, mold, and pests, ensuring their quality and safety during storage. Additionally, soybean storage silos are equipped with ventilation systems and temperature/humidity monitoring devices to maintain stable and suitable storage conditions.

Characteristics of soybean storage silo

Good sealing performance

Soybean storage silos typically have good sealing performance, effectively preventing moisture, pests, and other pollutants from entering, protecting soybeans from damage.

Ventilation system

To maintain air circulation and stable humidity inside the silo, soybean storage bins are usually equipped with ventilation systems to ensure that soybeans maintain good freshness and quality.

Temperature and humidity monitoring

Modern soybean storage silo may be equipped with temperature and humidity monitoring equipment, which monitors the environmental parameters inside the bin in real time for timely adjustment, ensuring that soybeans are stored under optimal conditions.

Sturdy and durable structure

The structure of soybean storage silos is typically sturdy and durable, capable of withstanding the weight of soybeans and the impact of external environments, ensuring long-term safe use.

Smart management

Some soybean storage silo may be equipped with smart management systems, allowing real-time monitoring and management of storage environments, improving management efficiency and accuracy.

Pest and mold prevention

To prevent pests and molds from damaging soybeans, soybean storage bins may undergo pest and mold prevention treatments, employing corresponding control measures to maintain the quality of soybeans.

Adjustability

Some soybean storage silo have adjustable features, allowing temperature, humidity, and other parameters to be adjusted as needed to meet different storage requirements, ensuring that soybeans are kept in optimal conditions.

Characteristics of soybean storage silo

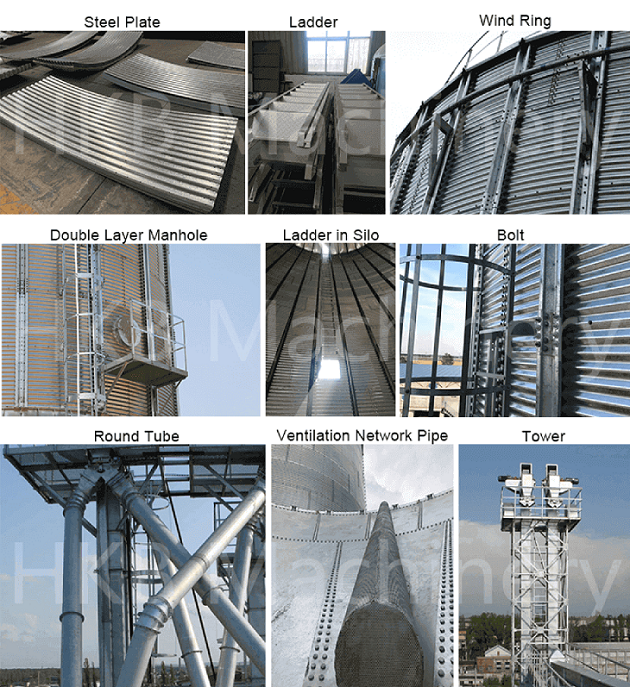

Wall

Forms the main structural enclosure of the silo, usually made of reinforced concrete, steel plates, or other durable materials, to support and protect the stored soybeans safely.

Roof

Covers the top of the silo, providing protection against rain, sunlight, and insulation. It is typically made of weather-resistant materials such as weatherboard or other corrosion-resistant materials to ensure the quality of the stored soybeans.

Floo

Located at the bottom of the silo, it supports the stored soybeans and facilitates the discharge of the soybeans. It may have a special design, such as a conical bottom, to facilitate the natural flow of soybeans.

Ventilation System

Includes ventilation openings, fans, and ventilation ducts to maintain air circulation and humidity stability inside the silo, preventing soybeans from molding and deteriorating.

Temperature and Humidity Monitoring Equipment

Used to monitor the temperature and humidity inside the silo, enabling timely adjustment and management of storage conditions.

Discharge Equipment

Includes discharge ports, conveying equipment, etc., used to remove the stored soybeans from the silo.

Structural Support

Components used to reinforce and support the silo structure, such as columns, beams, etc.

Safety Facilities

Including fire-fighting equipment, protective barriers, etc., to ensure the safety of stored soybeans and the safe operation of the warehouse.

Management System

Including intelligent management systems, monitoring equipment, etc., used to monitor and manage the operation status of the storage silo.

Advantages of soybean storage silo

Good sealing performance

Soybean storage silos typically have good sealing performance, effectively preventing moisture, pests, and other contaminants from entering, thus protecting soybeans from damage.

Ventilation system

To maintain air circulation and stable humidity inside the silo, soybean storage silos are usually equipped with ventilation systems to ensure that soybeans remain fresh and of high quality.

Temperature and humidity monitoring

Modern soybean storage silos may be equipped with temperature and humidity monitoring devices to monitor environmental parameters in real-time, allowing for timely adjustments to ensure optimal storage conditions.

Sturdy and durable structure

The structural design of soybean storage silo is typically robust and durable, capable of withstanding the weight of soybeans and the impact of external environmental factors, ensuring long-term safe usage.

Intelligent management

Some soybean storage silo may feature intelligent management systems to monitor and manage storage environments in real-time, improving management efficiency and accuracy.

Pest and mold prevention

To prevent pests and mold from damaging soybeans, soybean storage silo may undergo pest and mold prevention treatments, employing appropriate measures to maintain soybean quality.

Adjustability

Some soybean storage silos offer adjustable features, allowing temperature, humidity, and other parameters to be adjusted as needed to meet various storage requirements, ensuring soybeans remain in optimal condition.

Application scope of soybean storage silo

Coban Small Storage Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds,Coffee Beans, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Soybean storage silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |