rice storage silo

A rice storage silo is a facility specifically designed for storing rice, aimed at protecting the quality and safety of the rice and ensuring it remains unaffected

rice storage silo Introduction

A rice storage silo is a facility specifically designed for storing rice, aimed at protecting the quality and safety of the rice and ensuring it remains unaffected by dampness, mold, pests, or other contaminants during storage. Such grain silos typically feature specific structures and designs tailored to the storage requirements of rice, along with corresponding ventilation, monitoring, and management systems to maintain the rice in good condition throughout the storage process.

Characteristics of rice storage silo

Good sealing performance

Rice storage silos usually have good sealing performance, effectively preventing the intrusion of moisture, pests, and other contaminants, protecting rice from damage.

Ventilation system

To maintain air circulation and stable humidity inside the silo, rice storage silos are typically equipped with ventilation systems to ensure the rice remains fresh and of high quality.

Temperature and humidity monitoring

Modern rice storage silo may be equipped with temperature and humidity monitoring devices to continuously monitor environmental parameters inside the silo, allowing for timely adjustments to ensure the rice is stored under optimal conditions.

Sturdy and durable structure

The design of rice storage silos is typically robust and durable, capable of withstanding the weight of rice and external environmental factors, ensuring long-term safe use.

Smart management

Some rice storage silo may be equipped with smart management systems for real-time monitoring and management of storage conditions, improving management efficiency and accuracy.

Pest and mold prevention

To prevent pests and mold from damaging the rice, rice storage silos may undergo pest and mold prevention treatments, employing appropriate measures to maintain the quality of the rice.

Adjustability

Some rice storage silo feature adjustable parameters such as temperature and humidity, allowing for customization to meet various storage requirements and ensure the rice remains in optimal condition.

The structure of rice storage silo

Silo body

This is the main structure of the silo, typically cylindrical or rectangular in shape, and is where the rice is stored. It provides the necessary containment for the rice and is constructed using materials like concrete, steel, or aluminum.

Roof

The roof covers the top of the silo, providing protection against environmental elements such as rain, sunlight, and debris. It is designed to be sturdy and weather-resistant.

Ventilation system

The silo is equipped with a ventilation system to ensure proper air circulation inside the storage area. This helps regulate temperature and humidity levels, preventing moisture buildup and maintaining the quality of the rice.

Access doors

These are openings in the silo body that allow for the loading and unloading of rice. They are typically located at the top or side of the silo and may be equipped with locks or seals for security and protection.

Temperature and humidity monitoring equipment

Modern rice storage silos may include sensors and monitoring devices to track temperature and humidity levels inside the silo. This allows for real-time monitoring and adjustments to ensure optimal storage conditions.

Insulation

Some rice storage silos may feature insulation materials to help regulate temperature and prevent heat loss or gain, thereby preserving the quality of the stored rice.

Foundation

The foundation provides stability and support for the entire structure of the silo. It is typically made of reinforced concrete and is designed to withstand the weight of the stored rice and the forces exerted by environmental factors such as wind and seismic activity.

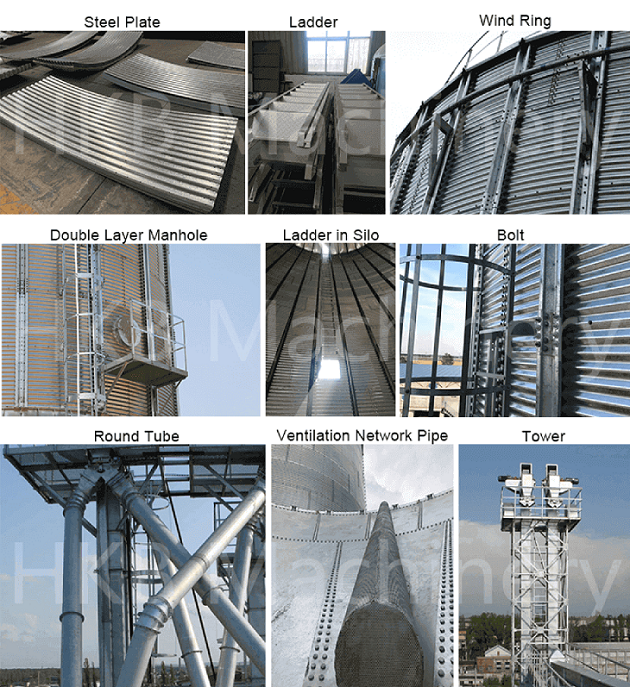

Auxiliary equipment

This includes items such as ladders, platforms, conveyors, and cleaning systems, which facilitate the loading, unloading, and maintenance of the silo. These components are essential for the efficient operation of the rice storage facility.

Advantages of rice storage silo

Maintaining rice quality

Rice storage silos provide a conducive storage environment, effectively controlling temperature, humidity, and ventilation, thus helping to preserve the freshness and quality of rice.

Pest and mold prevention

With appropriate storage conditions and preventive measures, rice storage silos can effectively prevent the breeding of pests and molds, reducing the risk of grain loss and quality degradation.

Improved storage efficiency

Rice storage silos employ advanced grain storage technology and equipment, enabling automated and intelligent management, thereby enhancing storage efficiency and reducing labor and management costs.

Reduced losses

With sturdy and durable structures, rice storage silos can effectively prevent grain from dampness, spoilage, and damage, reducing grain losses and waste.

Space saving

Rice storage silo can be designed and laid out according to needs, making full use of space, increasing grain storage density, and saving storage space.

Flexibility

Rice storage silo can be custom designed according to different storage needs and conditions, offering strong adaptability and flexibility to meet the requirements of different users.

Environmentally friendly and energy-saving

Some modern rice storage silo utilize energy-saving and environmentally friendly materials and technologies, resulting in lower energy consumption and environmental pollution, in line with the requirements of sustainable development.

Application scope of rice storage silo

Coban Small Storage Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds,Coffee Beans, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Rice storage silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |