Paddy storage silo

Paddy storage silo are facilities specifically designed for storing paddy rice, typically employing specialized designs and structures to ensure the paddy maintains good quality and safety during storage.

Paddy storage silo Introduction

Paddy storage silo are facilities specifically designed for storing paddy rice, typically employing specialized designs and structures to ensure the paddy maintains good quality and safety during storage. They are integral components of grain storage and supply chains. These silos typically feature functionalities such as moisture resistance, pest control, and ventilation to prevent issues like moisture absorption, mold growth, and pest infestation in the paddy.

Characteristics of Paddy storage silo

Moisture resistance

It is designed with moisture-proof measures to prevent paddy from getting damp, maintaining its dry state, and preventing mold and damage.

Insect prevention function

Equipped with insect prevention facilities such as spraying systems or physical isolation measures to effectively prevent pests from invading and protect the quality of the paddy.

Ventilation system

Equipped with ventilation equipment to keep the air inside the silo circulating, conducive to the ventilation of paddy, preventing heating and mold.

Sturdy structure

It adopts a sturdy and durable structural design capable of bearing the weight of the paddy and the impact of external conditions, ensuring the stability and safety of the storage silo.

Intelligent monitoring

Some modern paddy storage silo are equipped with intelligent monitoring systems that monitor storage environment parameters such as temperature and humidity in real-time to ensure that the paddy is stored under optimal conditions.

Efficient management

Equipped with efficient management systems such as remote monitoring and traceability systems to improve the efficiency and accuracy of storage management.

Environmental sustainability

It uses environmentally friendly materials and energy-saving equipment to reduce energy consumption and environmental impact, achieving sustainable paddy storage.

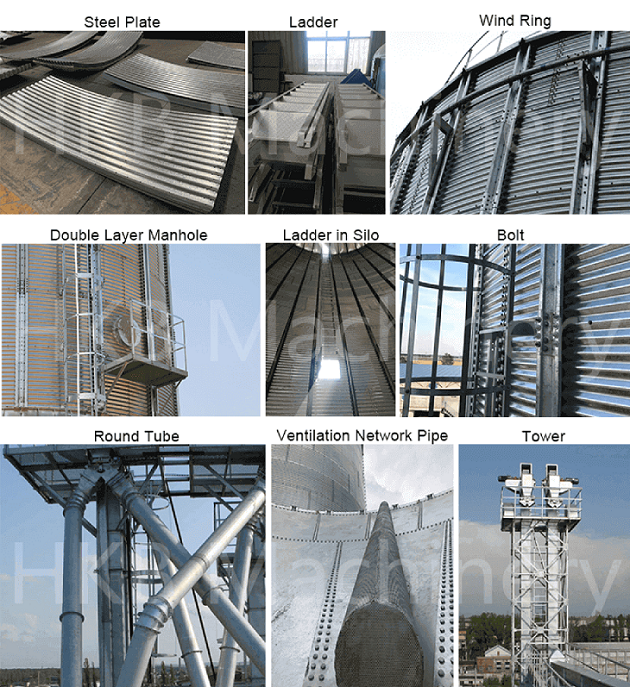

The structure of Paddy storage silo

Silo Body

This is the main component where the paddy is stored. It is typically cylindrical or rectangular in shape and made of durable materials such as steel or concrete.

Roof

The roof covers the top of the silo, protecting the stored paddy from weather elements such as rain and sun. It is designed to be watertight and may have ventilation openings for air circulation.

Ventilation System

This includes ventilation openings, fans, and ducts to facilitate air circulation inside the silo, preventing heat buildup and moisture accumulation, which can lead to paddy spoilage.

Access Points

These are openings in the silo for loading and unloading paddy. They may have covers or doors to seal the silo when not in use.

Support Structure

The silo is supported by a sturdy framework or foundation, which provides stability and strength to withstand the weight of the stored paddy.

Temperature and Moisture Monitoring System

Some silos may be equipped with sensors and monitoring devices to track temperature and moisture levels inside the silo, ensuring optimal storage conditions for the paddy.

Safety Features

This includes measures such as fire detection and suppression systems, as well as safety equipment like ladders and guardrails to ensure safe operation and maintenance of the silo.

Ancillary Equipment

This may include conveyors, elevators, and cleaning systems for loading, unloading, and processing the paddy inside the silo.

Advantages of paddy storage silo

Moisture and pest resistance

It has good moisture and pest resistance, effectively preventing paddy from getting damp, molding, and being invaded by pests.

Ventilation and breathability

Usually equipped with a ventilation system to maintain the freshness and quality of the paddy, preventing mold growth and heat accumulation.

Structural stability

The storage silo has a sturdy and durable structure, capable of bearing the weight of the paddy and maintaining stability.

Environmental health

It adopts environmentally friendly materials and designs to ensure that the stored paddy meets food safety and hygiene standards.

Intelligent management

Some storage silos are equipped with intelligent management systems that can monitor and adjust storage environments in real-time, improving management efficiency and accuracy.

High efficiency and energy saving

It adopts energy-saving designs and equipment to improve energy utilization efficiency and reduce operating costs.

Flexibility and controllability

It has flexible operation and control functions, allowing storage conditions to be adjusted according to needs to meet different storage requirements.

Safety and reliability

Equipped with safety facilities and measures to ensure the safety and reliability of the storage process, preventing accidents from occurring.

Application scope of Paddy storage silo

Coban Small Storage Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds,Coffee Beans, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Paddy storage silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |