Storage Grain Silo

A Storage Grain Silo warehouse is a facility specifically designed for storing various grains (such as rice, wheat, maize, etc.), aiming to provide safe

Storage Grain Silo Introduction

A Storage Grain Silo warehouse is a facility specifically designed for storing various grains (such as rice, wheat, maize, etc.), aiming to provide safe, dry, pest-resistant, and moisture-proof storage conditions to ensure the quality and shelf life of the grains. These warehouses typically feature specialized designs and structures, including well-sealed walls and roofs, ventilation systems, temperature and humidity control equipment, etc., to meet the storage requirements of different types of grains. The construction and management of Storage Grain Silo warehouses are crucial links in the grain industry chain, playing an important role in ensuring food supply, reducing grain losses, and safeguarding food security.

Main features of grain storage silo

Large-Capacity Storage

Grain storage silo typically have a large storage capacity, capable of meeting the centralized storage needs of a large amount of grain. This is of great significance for ensuring the supply security and stability of grain.

Good Sealing Performance

The design of the silo takes sealing performance into account, which can effectively prevent the intrusion of external air, moisture, and pests, thereby maintaining the quality and storage safety of the grain.

Moisture and Mold Prevention

By controlling the temperature and humidity inside the silo, grain storage silo can provide a good storage environment to prevent grain from getting damp and moldy, ensuring that the grain remains dry and clean during storage.

Sturdy Structure

Grain storage silo are usually made by welding high-strength steel plates, with a sturdy and durable structure that can withstand significant pressure and impact, ensuring safety during storage.

High Level of Automation

Modern grain storage silo are equipped with advanced automated control systems that can achieve automatic material intake and discharge, automatic monitoring, and automatic alarming functions, improving storage efficiency and reducing labor costs.

Easy to Manage

The design of grain storage silo takes into account the convenience of management, usually equipped with facilities such as inspection ports and observation windows, making it convenient for staff to carry out daily inspections and maintenance.

Environmental Protection and Energy Saving

Grain storage silo focus on environmental protection and energy saving in the design and manufacturing process, using environmentally friendly materials and energy-saving technologies to reduce energy consumption and pollution emissions, in line with the requirements of sustainable development.

Strong Adaptability

Grain storage silo can be customized according to different needs and site conditions, with strong adaptability, capable of meeting the storage needs of various types of grain.

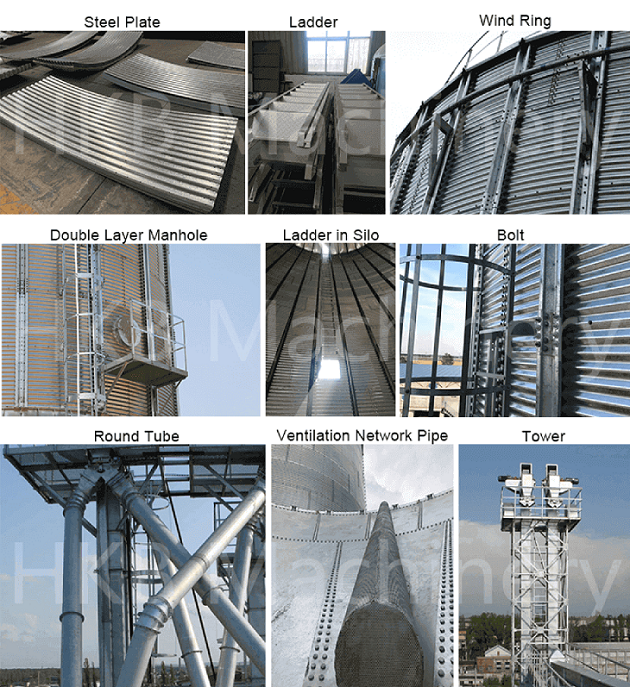

Main structure of grain storage silo

Silo Body

This is the main part of the silo, typically made by welding steel plates to form a cylindrical enclosed space. The interior of the silo body is designed for grain storage, taking into account the flowability and storage density of the grain to ensure even distribution and full utilization of space.

Silo Roof

The silo roof is the top structure of the silo, usually designed as a cone or dome shape to reduce the impact of wind and rain on the silo body. The roof also features an inlet for the introduction of grain.

Silo Bottom

The silo bottom is the bottom structure of the silo, commonly designed in a conical shape to facilitate the smooth outflow of grain. The bottom is equipped with an outlet that can be connected to conveying equipment to transport grain to where it is needed.

Support Structure

The support structure is the skeleton of the silo, used to bear the weight of the silo body and roof. The support structure typically consists of steel columns or frames to ensure the stability and safety of the silo.

Ventilation System

The ventilation system is used to maintain air circulation and dryness inside the silo, preventing the grain from becoming damp and moldy. The ventilation system usually includes equipment such as vents, ducts, and fans, which can be adjusted according to the required ventilation volume.

Temperature Monitoring System

The temperature monitoring system is used to monitor the temperature inside the silo in real time to detect anomalies promptly and take measures. The temperature monitoring system typically includes equipment such as temperature sensors and monitoring instruments.

Main advantages of grain storage silo

Space-Saving

The land area occupied by steel silos for grain storage is only a quarter of that required by traditional warehouses, making full use of space and effectively saving land resources.

Grain Storage Safety

Steel silo can ensure the quality of grains such as wheat, rice, and corn, free from pest infestation. As long as the moisture content is controlled within a safe range, their safe storage period is the same as that of grain stored in traditional warehouses, with the optimal storage period being approximately 3 years.

Convenient Operation, Safe and Efficient

Compared to the significant labor force needed for grain storage in warehouses, steel silos require minimal personnel to operate. The supporting systems of steel silos are comprehensive, the processes are flexible, and the level of automation is high. Operators can manage the entire silo from an indoor control room.

Low Construction Cost, Fast Construction

Steel silo are lightweight and cost-effective, with a total investment cost lower than that of traditional warehouses. The construction period is short and not affected by seasonal or weather conditions.

Good Overall Performance, Long Service Life

The overall strength, stability, and seismic resistance of steel silos are superior to those of grain stored in warehouses. The normal service life can reach 20-50 years, or even longer.

Excellent Airtight Performance

The sealing performance of steel silos is particularly good, allowing for the storage of powdery materials such as grain, cement, fly ash, and ultra-fine slag powder, which has a wide range of applications in the construction materials industry.

Large Storage Capacity

The grain silo, designed with a three-dimensional spatial layout, allow for full utilization of the grain and have a large storage capacity.

Effective Preservation

Due to the cylindrical design of the exterior, the pressure inside the silo is evenly distributed, and the grain is not affected by the external environment, resulting in good preservation effects.

Strong Seismic Resistance

The cylindrical shape of the silo provides excellent seismic resistance, ensuring that the grain inside remains undamaged, especially during earthquakes.

Application scope of Storage Grain Silo

Agricultural Sector

Agriculture is one of the primary application fields for steel silo. In terms of on-farm grain storage, steel silos are widely used for storing various cereals such as wheat, corn, and soybeans, due to their excellent sealing properties, wind resistance, and strong storage capacity.

Food Industry

Steel silo also have a broad range of applications in the food industry, particularly in the storage of raw materials and finished products for large grain and oil companies. Since steel silos can be constructed into various shapes and sizes with a multitude of accessories, they can conveniently adapt to the needs of various grain and oil storage facilities.

Bulk Grain Loading, Storage, and Transportation

Bulk grain silo are a common type of grain storage facility used in major grain importing and exporting countries worldwide. They play a role in regulation, turnover, and buffering during the loading, storage, and transportation of bulk grain.

Storage Grain Silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |