feed silo

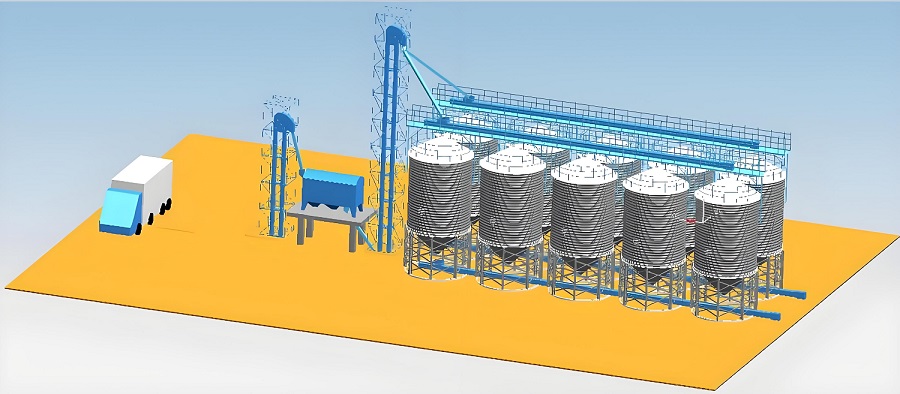

A feed silo is a vertically oriented container or structure specifically designed for the storage of feed, commonly utilized in medium to large-scale poultry farms

feed silo Introduction

A feed silo is a vertically oriented container or structure specifically designed for the storage of feed, commonly utilized in medium to large-scale poultry farms, livestock operations, and related feed processing and distribution facilities. The primary purpose of a feed silo is to safely, economically, and efficiently store large quantities of granular or powdered animal feed, ensuring its quality remains stable and readily available for supply to animals as needed.

Feed Silo Features

Structural Design

Feed silos typically adopt cylindrical or square structures to maximize storage space and ensure structural stability. The materials used for the silos must be durable and have good sealing properties to prevent the ingress of moisture, pests, and other environmental factors that could affect the quality of the feed.

Temperature and Humidity Control

To maintain the quality of the feed, silos may be equipped with temperature and humidity control systems. These systems help to maintain a suitable storage environment, preventing the feed from becoming damp or overly dry.

Ventilation System

Good ventilation is essential to prevent feed spoilage and extend the storage life. Silo designs usually include vents or ventilation equipment to ensure air circulation within the silo, reducing the risk of odors or spoilage due to prolonged storage.

Loading and Unloading System

To facilitate the entry and exit of feed, silos are fitted with specialized loading and unloading systems, such as screw conveyors and pneumatic conveying systems. These devices ensure the rapid, efficient, and safe handling of feed.

Cleanliness and Hygiene

The design of feed silos must consider the requirements for cleanliness and hygiene. The interior of the silo should be easy to clean to prevent contamination and the growth of pathogens, ensuring the sanitary safety of the feed.

Automation and Monitoring

Modern feed silos may utilize automation technologies, including monitoring systems and control software, to track the storage status of the feed and the environmental conditions of the silo in real-time, achieving intelligent management.

Safety Measures

The design of feed silos must also consider safety factors, such as fire prevention and explosion protection. Therefore, silos may be equipped with fire-fighting equipment, explosion-proof designs, and emergency measures for situations that require immediate response.

Feed silo structure

Silo Body

This is the main part of the silo, usually cylindrical or square in shape, designed to hold a large volume of feed. The silo body must be constructed from durable materials with good sealing properties to prevent the ingress of moisture, pests, and other environmental factors.

Top Structure

The top structure of the silo is designed to prevent rainwater and pests from entering, and may also include ventilation openings or equipment to regulate air circulation and control temperature and humidity inside the silo.

Bottom Structure

The bottom of the silo is typically conical or funnel-shaped to facilitate the flow and discharge of feed. The bottom structure includes the discharge outlet and related conveying equipment, such as screw conveyors or pneumatic conveying systems.

Temperature and Humidity Control System

To maintain an optimal storage environment, the silo may be equipped with temperature and humidity control devices, such as heaters, coolers, and dehumidifiers.

Ventilation System

The ventilation system ensures air circulation within the silo through the placement of vents or the use of fans, reducing the risk of spoilage or odor development due to prolonged storage of feed.

Loading and Unloading System

The loading and unloading system comprises equipment used to transfer feed into and out of the silo, such as conveyor belts and elevators, to improve operational efficiency.

Monitoring and Automation System

Modern feed silos may be fitted with monitoring cameras, sensors, and automated control systems to monitor the conditions inside the silo in real-time and manage it automatically.

Safety Facilities

To ensure operational safety, the silo may include fire-fighting equipment, explosion-proof measures, and emergency alarm systems.

Cleaning System

Considering the hygiene requirements of feed, the silo may be equipped with a cleaning system to periodically clean the interior of the silo and prevent contamination.

Feed Silo Advantages

Efficient Space Utilization

The design of feed silos typically features cylindrical or square structures, which provide a large storage capacity within a limited space. Compared to traditional flat warehouses, silos can store a greater amount of feed on a smaller footprint.

Optimal Storage Conditions

Silos are specially designed to offer good ventilation, helping to maintain suitable internal temperature and humidity levels. This prevents feed from becoming damp, overheating, or molding, effectively protecting the quality of the feed.

Automation

Silos are usually equipped with modern material management systems that support automated control of material intake and outtake, as well as inventory management. Real-time monitoring technology allows for accurate tracking of the quantity and condition of materials inside the silo.

Reduced Losses

The design of silos minimizes losses during the loading and unloading process and prevents spoilage or contamination due to improper storage, thus reducing waste and loss.

Ease of Cleaning and Maintenance

The internal structure of silos is designed for easy cleaning and maintenance, contributing to the sanitary safety of the feed and also reducing maintenance costs and time.

Safety Features

The design of feed silos takes safety into account, including fire prevention and explosion protection measures, ensuring the safe and reliable storage process.

Environmental and Energy Efficiency

The design and operation of silos focus on environmental protection and energy saving, reducing energy consumption through optimized design and minimizing the impact on the environment.

Application scope of Feed Silo

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Feed Silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |