Sunflower seed cone bottom silo

Sunflower seed cone-bottom silo are storage units specifically designed for the storage of sunflower seeds, featuring a conical bottom structure

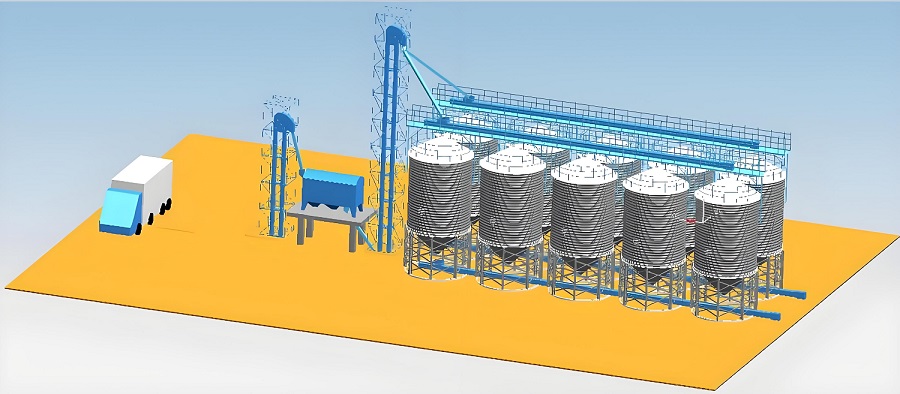

Sunflower seed cone bottom silo Introduction

Sunflower seed cone-bottom silo are storage units specifically designed for the storage of sunflower seeds, featuring a conical bottom structure that allows for the self-flow unloading of the seeds through the force of gravity when required. This design enhances the efficiency of discharge operations and minimizes the need for manual intervention. Typically constructed from materials such as galvanized corrugated panels, these silos offer excellent corrosion resistance and moisture protection, ensuring that the sunflower seeds are safeguarded from environmental influences and their shelf life is extended.

Features of sunflower seed cone bottom silo

Conical Bottom Design

The conical bottom facilitates the self-flow discharge of sunflower seeds, making it easier to extract and transport them quickly.

Materials and Structure

Durable materials like galvanized corrugated panels are used to ensure the long-term stability and corrosion resistance of the silo.

Capacity Range

The volume of individual sunflower seed cone-bottom silos can range from a few cubic meters for smaller units to several thousand cubic meters for larger ones, catering to various storage requirements.

Durability

The design and material selection of sunflower seed cone-bottom silos make them suitable for long-term storage and capable of withstanding various climatic conditions.

Maintenance

The conical bottom design makes cleaning and maintenance of the silo interior relatively simple, which helps to maintain the quality of the sunflower seeds.

Versatility

While specifically suitable for sunflower seed storage, cone-bottom silos can also be adapted for the storage of other types of grains or granular materials as needed.

Sunflower seed cone bottom silo structure

Conical Roof

The roof of the silo is usually conical, designed with an angle of approximately 30 degrees to facilitate the smooth runoff of rainwater and other liquids, preventing water accumulation at the top.

Silo Body

The silo body is the main part that houses and stores the sunflower seeds. It is constructed from corrugated metal sheets and structural steel panels with a high degree of galvanization, ensuring long-term resistance to atmospheric elements.

Conical Bottom

The conical bottom is an essential part of the silo, facilitating the self-flow unloading of sunflower seeds, reducing the need for manual intervention and enhancing extraction efficiency. The slope of the cone bottom may vary, with angles of 40, 45, or 60 degrees, with the 60-degree cone bottom being suitable for storing颗粒 and powdery materials with higher viscosity.

Discharge System

The discharge system includes the hopper at the bottom and possible discharge mechanisms such as screw conveyors or pneumatic conveying systems, ensuring the smooth outflow of sunflower seeds.

Supporting Structure

The supporting structure, including columns and beams, supports the weight of the silo and ensures the stability of the structure.

Seals and Insulation

Seals are installed at the joints of the metal sheets to maintain a watertight seal over the long term, preventing water ingress. Insulation layers may consist of steel plate polyurethane or rock wool, with color steel profile sheets installed on the outside as the outer silo panel.

Manholes and Maintenance Facilities

Manholes are typically provided for easy access by operators to carry out cleaning and maintenance work inside the silo.

Application scope of Sunflower seed cone bottom silo

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Advantages of sunflower seed cone bottom silo

Enhanced Storage Safety

By researching and improving storage silo types, equipment for entering and exiting the silo, and discharge methods, cone-bottom silos effectively address the issue of quality deterioration of sunflower seeds during storage, thereby enhancing the safety of storage.

Self-Flow Discharge

The design of the cone-bottom silo allows sunflower seeds to self-flow under the influence of gravity, reducing the need for manual intervention, increasing discharge efficiency, and also lowering labor intensity.

Reduced Residue

Compared to flat-bottom silos, the conical structure effectively reduces the accumulation and residue of sunflower seeds at the bottom, achieving near “zero dead corners,” reducing material waste and improving overall storage utilization.

Preventing Arching

The conical bottom helps to disperse the pressure of sunflower seed accumulation, reducing local stress concentration and lowering the risk of arching due to long-term static storage, ensuring even distribution of the material within the silo for smooth subsequent discharge.

Improved Ventilation

The bottom of the cone-bottom silo typically features vents or air ducts, which, combined with the conical shape, promotes even air circulation through the sunflower seed pile, enhancing the efficiency of the ventilation system and helping to keep the seeds dry, preventing mold and overheating.

Reduced Pest Infestation

The absence of accumulated material at the bottom of the cone-bottom silo reduces the presence of damp and dark corners, lowering the chances of pest and microbial breeding, which is beneficial for maintaining the quality of sunflower seeds.

Ease of Cleaning

The conical structure results in a smaller bottom area of the silo and no dead corners, making cleaning work easier. Whether it’s mechanical sweeping or manual clearing, it can be efficiently accomplished, reducing maintenance costs.

Optimized Space Utilization

Although the cone-bottom silo occupies some space at the bottom, its good self-flowing and low residue characteristics allow for more effective use of the silo volume overall, especially in scenarios requiring frequent discharge, where its comprehensive economic benefits are more prominent.

Structural Stability

The structural design of the cone-bottom silo takes into account stability and durability, being able to withstand the weight of the sunflower seeds and resist the impact of external environments, such as wind, rain, and snow.

sunflower seed cone bottom silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.