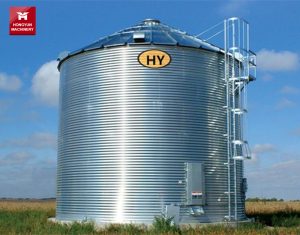

grain silo

A grain silo is a building or facility designed for the storage and preservation of grain. Its primary purpose is to provide a dry, clean, and safe environment for the grain, protecting it from dampness, contamination, pests, and other factors that may cause damage.

grain silo Introduction

A grain silo is a building or facility designed for the storage and preservation of grain. Its primary purpose is to provide a dry, clean, and safe environment for the grain, protecting it from dampness, contamination, pests, and other factors that may cause damage. grain silo play a crucial role in agricultural production, grain reserves, and the management of the grain supply chain.

grain silo structure

Roof Top

the roof is designed to stand up even the harshest environment of extreme snow disaster with the echo of top and down part strong structure and connecting radial ribs which is Z interconnected again itself. grain silo Roof panels incorporate with ribs with over and under lap profiles ensuring a precise fit.

Body Steel Plate

A commercial 275g/m2 double galvanized steel coating increases life and durability. 450g/m2 and 600g/m2 coating available for customized orders. Each sidewall sheet is manufactured from high-tensile steel that can overcome extreme power, pressure.

Stiffeners

coban high tension stiffener(can be located inside or outside the grain silo,) profiles make bins stronger allowing to stand well even under an extreme hurricane. Base stiffener boots are coated so they won’t rust over time.

Wind Ring

For tall grain silo or that need to resist heavy wind. Wind ring and brackets reduce bolt holes in stiffeners; Swaged technology ensure grain silo power load capacity.

High strength bolts and screws

coban high strength bolts paired with sealing washers, coated hardware provides added protection from rust to ensure your grain silo bin stands the test of time.

Manhole

Double layer security locking manhole system.

Wide Flange H Beam Support Structure

The wide flange H-Beam support structure has the strength and durability to support the heavy hopper bottom silo loads for a long time, and with consideration of wind and seismic requirements.

Grain silo features

granary, as specialized facilities for storing grain, possess a range of unique characteristics designed to ensure the safety, efficiency, and long-term preservation of grain. Here are the main features of grain silo:

1. Specialization

The design and construction of grain silo specifically cater to the needs of grain storage, including special requirements for temperature and humidity control, moisture resistance, pest prevention, and ventilation.

2. Durability and Sturdiness

The structure of grain silo must be robust enough to withstand the weight of the grain and potential environmental loads, such as wind and snow, ensuring long-term stability and use.

3. Insulation and Thermal Retention

silo typically have good insulation and thermal retention properties to maintain a suitable storage environment and prevent damage to the grain due to excessively high or low temperatures.

4. Waterproof and Moisture-Resistant Design

The design and construction of silo must ensure waterproofing and moisture resistance to prevent rainwater seepage and ground moisture rise, both of which could lead to grain spoilage.

5. Airtightness

silo need to have good airtightness to prevent the entry of pests and outside air, maintaining a stable environment within the storage.

6. Ventilation System

granary are equipped with ventilation systems, which can be natural or mechanical, helping to regulate the temperature and humidity inside, keeping the grain fresh and dry.

7. Efficient Loading and Unloading Systems

Modern silo are designed with loading and unloading efficiency in mind, equipped with advanced loading and unloading equipment and systems, such as conveyor belts and elevators, to improve work efficiency and reduce losses.

8. Information Management

Modern silo increasingly adopt information management systems, achieving functions such as grain condition monitoring, inventory management, and data analysis, enhancing management efficiency and accuracy.

9. Environmental and Energy Efficiency

grain silo focus on environmental protection and energy conservation in their design and operation, using energy-efficient building materials and equipment, and implementing waste recycling measures.

10. Emergency Reserve Capacity

granary have the function of emergency reserves, capable of quickly allocating grain in emergencies to ensure the stability of grain supply.

11. Multifunctionality

In addition to the basic grain storage function, some granary also have other functions such as processing and distribution, forming an integrated service system.

12. Safety

The design and operation of silo must comply with safety standards, including fire prevention, explosion protection, and dust control measures, to ensure the safety of personnel and grain.

These char

Grain silo application scope

Coban Silo is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

Grain silo technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.